When Auckland International Airport’s terminal was inundated by flood waters on the Friday of Auckland Anniversary weekend in January this year, Atrax Group heeded the call for help.

A quickly-assembled crisis response team assessed the damage to scales and baggage conveyors. Atrax provided the airport with temporary scales to help get the international terminal back up and running by Sunday morning – just over 30 hours after the event – and then set to work repairing 165 flood damaged scales and check-in baggage conveyors and replacing damaged components. Legacy non-Atrax control systems that were destroyed were replaced with modified Atrax CCN-8 SoftDrive conveyor control nodes to get them operational rapidly.

On Friday 27 January 2023, now declared Auckland’s wettest day on record by NIWA (New Zealand’s National Institute of Water and Atmospheric Research), Auckland International Airport (AIAL) suffered severe flooding and damage on its runway and in its international terminal building. The airport recorded 258 mm of rain that day – significantly more than its average rainfall for the whole month (201 mm). The entire check-in/departures and arrivals area was flooded, laying waste to scales and baggage conveyors, along with the low-level control systems.

Auckland International Airport flooding footage | The Telegraph

All the scale bases, with their precision load cells and junction boxes, were submerged for up to 24 hours. All the distributed I/Os (that is, signalling and control logic cables and distributed control networking modules), and the 400 V three-phase mains power cables and local motor starters, plus many of the check-in conveyor drum motors and other motor gear boxes, with their associated controls, were also submerged.

“As we know, water and electricity don’t mix well together,” says Kevin Maurice, Atrax Group’s managing director. “The submerged 400 V cables were dangerous and caused a lot of equipment damage. Stray voltages and leakages damaged low voltage signalling controls and precision scales. As the floodwater had picked up mild contaminants while it flowed overland toward the terminal, the water corroded electronic circuit boards, flooded cables and caused electrical leakage. Dust in the equipment turned into mud, resulting in a soggy conductive mess – which played havoc with equipment.”

Mobilising for action

“When we got the initial call, only a few battery powered self-check scales were estimated to be affected,” Kevin says, “but my engineering manager quickly realised that this would be a much bigger problem than first thought. He put other service providers on notice and, once the flood water was pumped out, went to the airport to conduct an onsite assessment of the damaged equipment, and let them know that ALL the scales would be affected.” Atrax mobilised accordingly.

Kevin quickly assembled an emergency response team comprised of his engineering manager, production & procurement manager, senior controls engineer, several field service engineers, a systems engineer, production technicians and production engineer and service technicians and service assistants. Kevin took on the role of leading and coordinating the team and being the liaison between AIAL, Air New Zealand and the other key contractors called in to help – including Daifuku Oceania, Neo Consulting and Alstef Asia Pacific (formerly Glidepath).

“We were anticipating and thinking ahead – being very proactive,” Kevin says. “My engineering manager was onsite at AIAL managing the scale assessments, repairs and certifications. I went into the office on Saturday to establish what spare parts and stock we had and what we could easily and quickly source, and assess our capability to help address the damage.

“All of the AIAL check-in scales (manned) and the bag-drop and check-in kiosks (unmanned and automatic) are Atrax scales. A mixture of older and newer scale bases and controls were damaged. You’d think it might be a problem getting these going again – but we hunted globally for essential items including connectors, cables and obsolete load cells that were in many of the older scales. We were fortunately able to start replacing parts and fixing scales from Saturday afternoon,” Kevin says.

With planes grounded and thousands of passengers needing to catch flights, AIAL’s immediate need was for temporary legal-for-trade scales to get the airport going again on Sunday. A team of four worked through until 2:00am on Sunday morning preparing, calibrating and certifying 20 temporary loan scales to allow limited airport operations to commence from 9:00am on Sunday.

CCN-8 SoftDrive saves the day

The initial onsite damage inspection meeting on Sunday morning was to assess the damage and work out a plan to get the scales and check-in conveyors running again.

While scales could be repaired where possible, the existing legacy (non-Atrax) controls on the conveyors were rendered inoperable by the flood waters. It was not economically viable, nor easy, to repair or replace them – in many cases there were no replacements available in the country. Replacing all the damaged controls could have taken weeks, if not months, says Kevin Maurice. “We needed a ready alternative. My senior controls engineer, who was out of Auckland for the weekend, drove back up on Sunday morning and after assessing the check-in conveyor controls, helped determine a rapid solution to get the check-in conveyors working to allow nearly normal check-in operations.”

This solution used the CCN-8 SoftDrive conveyor control node – a solid-state, soft-start 400 V conveyor motor control device. The plan was to disconnect all the old controls and motors and reconnect them to the CCN-8 SoftDrives, which can be operated by push-button.

“We agreed to a trial run on Sunday morning, and by the afternoon concluded it would work,” Kevin says. “We installed a single lane of Atrax CCN-8 SoftDrives to prove our proposed solution. By Sunday afternoon we had one check-in lane operational with working scale and induct conveyors.

“We didn’t have enough CCN-8 SoftDrive units on the shelf, but I did know we had 800 units packed and ready for a project in the Middle East – so I liberated 120 units from this cache.

“A modification needed to be made to allow the CCN-8 SoftDrives to run under local control, not as part of a network. Note that this was the AS-i variant, the PROFINET variant does not have an auxiliary input to connect to a push-button.

“Our software team in Christchurch made the modification to the CCN-8 software to enable it to work at AIAL. They tested it and then emailed the change up to Auckland. All of this work was done on Sunday.

“The modified software was tested in the factory and then the local electrical service teams (Daifuku Oceania and Sharp Data Electrical) installed, tested, made some configuration adjustments, and approved the unit for use. The CCN-8 SoftDrive units were unboxed, reprogrammed, configured, and installed over Sunday/Monday. This work was overseen by Neo Consulting, on behalf of AIAL.

“Over the rest of the week, Atrax also sourced and supplied the required cables. Starting on Sunday, Atrax teams started rolling out and repairing scale bases – replacing all junction boxes and cables, along with any damaged load cells, weight displays and power supplies where necessary. We had two to three teams of people working long days at the airport. Then, we also had four to five people at Atrax working on the scales, controls and cables.”

Baggage handling system upgrade accelerated

AIAL had already planned a major upgrade to its baggage handling system. Due to the flooding, this project was brought forward and is currently underway to make more permanent repairs and update controls to current technology. The upgrade includes 308 new CCN-8 SoftDrive PROFINET units and these will form part of the permanent flood repairs.

“The difference between the AS-i and PROFINET variants of the CCN-8 SoftDrive is the communications bus (data highway). They are all connected to the communications channel and all have their own unique address and talk to the host over this data highway. AS-i is very simple and binary – turns on and off. It’s a lower level I/O (in/out) control. PROFINET is more complex – it has a higher level of communication and provides more data back and forth. It’s not just a simple on/off unit,” Kevin explains.

Teamwork and responsiveness acknowledged

In an email, Auckland Airport chief executive, Carrie Hurihanganui, thanked everyone involved for their efforts in helping to get AIAL operational again following the flood. She wrote:

“It seems remarkable that almost two weeks ago, the city of Auckland experienced rainfall unlike anything seen before. That record-breaking deluge also brought with it an amazing airport community response to the subsequent flooding – one that saw the international terminal up and running just over 30 hours after the event.

“The airport is an ecosystem with a multitude of organisations that come together to get people where they need to be. That has certainly proved true over the past couple of weeks!

“I want to share my sincere gratitude for the huge effort you and your organisation contributed to the restart of airport operations enabling the backlog of stranded passengers get to their destination.”

Kevin Maurice says he thinks his team’s response is unparalleled: “If the airport used foreign scales, they could’ve been waiting weeks for parts, and additional skilled technicians and engineers. We were very lucky we had stock available and were able to quickly source extra parts that we didn’t have on hand. Having a large stockpile is not usual. We take pride in delivering excellent products backed by outstanding service. We were willing and able to respond, amid our usual high-demand production work, new installations and also other New Zealand clients with similar needs following the flooding. Despite the supply chain challenges, we were able to pull stock and help fix AIAL’s issues – pretty amazing, really. I’m extremely proud of the efforts of my team. I’m also in awe of how everyone came together, pooling resources and hundreds of collective years of brainpower to help solve the challenges AIAL faced.”

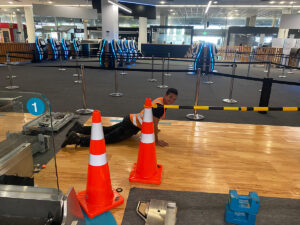

Photo gallery: Atrax in action

View the photo gallery to see the Atrax team in action. Note: click on any image to see a full-size version. Click the ‘back/return’ arrow to go back to the article.

More information

Want to know more about Weightrax for your organisation? We’d be happy to tell you more and give you a demonstration.

Source note: this article was originally published on Weightrax’s parent company Atrax Group’s website, 13 July 2023. It is republished here with permission. You can read the original article here.